METAL STRUCTURES

We have the experience and equipment for the manufacture and production of technological metal structures, with different purposes for the oil and gas sector and the energy sector.

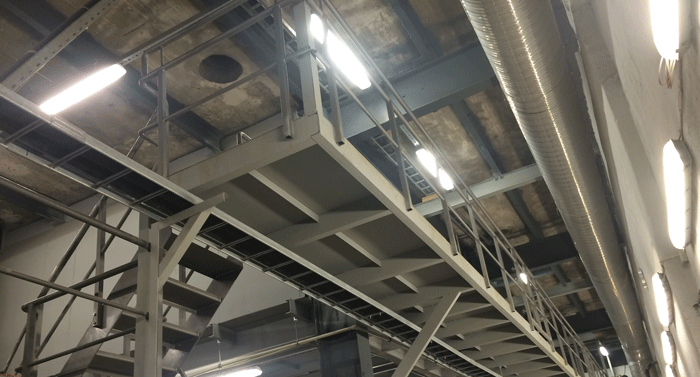

We can production metal structures platform for service, stairs, catwalks, and the metal construction of reservoirs.

Production of metallic junctions between buildings and production facilities for service personnel.

Service platforms are used in all branches of industry and production. For service platforms use of a metal grid decks that meet all necessary design requirements.

Carried out anti-corrosion painting of metal structures.

We repair receptacles (metal, polyethylene and polypropylene) using professional equipment.

STRUCTURES OF POLYETHYLENE AND POLYPROPYLENE

Various non-standard products of polyethylene and polypropylene.

Repair plastic receptacle is carried out by specialists. Most contemporary receptacles are made of plastic. The most popular types of plastics for the production of receptacle are polyethylene and polypropylene.

Repair plastic receptacles has become possible after the advent technology of welding plastics. Repairs performed using polyethylene handheld welding extruders.

Polyethylene is resistant to chemicals and frost, is an excellent insulator, has shock-resistant properties when heated, it becomes softer (at 80-120 °C), harden when cooled, has an extremely low adhesion (sticking), so any glues and tar cannot be used for repair and restoration of this material.

We repair any plastic tanks: tanks for alkali tank acid, receptacles for salt solutions and other chemical solutions. The restoration of receptacles would be a good solution for any user and will allow to significantly save the budget for both private individuals and large companies.

Lining of reservoirs and premises with plastic

Lining, coating of internal surfaces of metal bodies receptacles and premises with the use of chemically resistant materials, protects the wall of buildings from damage arising from the impact of solutions, and protects the solution from contamination by the products of dissolution of the material of the walls. In addition, the lining of metal baths, which are used for holding electrochemical processes, prevents the passage of current to the body of the bath.

Polypropylene has: high mechanical strength, high resistance to shock loads, ductility, inertness to most chemical reagents. The main advantage of polypropylene is the ability to use at high temperatures, and in combination with other properties of the material, provides broad prospects for the use of polypropylene for the lining baths the liner method for the manufacture of other equipment used for galvanic shops: board suction, ventilation ducts, covers for baths, drums.

We produce non-standard products from polyethylene and polypropylene by design of the customer.